Retrofit Of Inge’s Ultrafiltration System

With “TORAYFIL” UF Modules

Industry: Paper

Date : April/May-2023

Capacity: 7MLD

Project Background

Challenge

Fiber Breakage:

The existing UF system faced persistent issues with fiber breakage within a year of operation. This not only increased the frequency of Cleaning in Place (CIP) procedures but also compromised system reliability and raised concerns about water quality.

Fiber Breakage:

Elevated SDI levels were a common occurrence, leading to fouling of the RO membrane.

This necessitated extra maintenance and operational expenses.

High Inorganic Load

Average feed suspended & Inorganic load is very resulting into failure of Inge’s In-out mechanism

TSS <50

Turbidity <50

COD <350

Solution

| Inge (Previous) |

Toray (New system) |

|

|---|---|---|

| Plant capacity | 7 MLD | 7 MLD |

| No. of Train | 2 Nos | Train -1 |

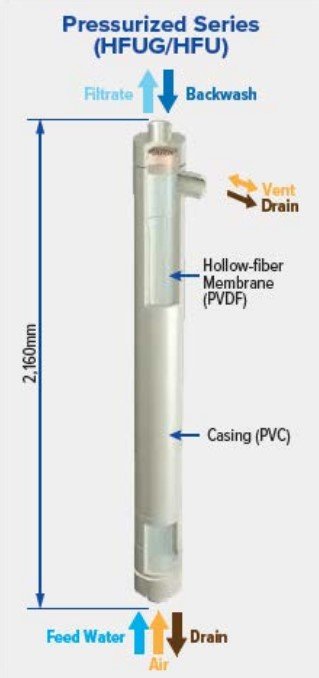

| Model | Dizzer XL | HFUGB2315 AN |

| Surface area | 80 m2 | 75m2 |

| Qty | 60 Nos | 50 Nos |

| MOC | PES | PVDF |

| Nominal pore size | 0.02 micron | 0.01 micron |

| Mode of operation | IN – Out | Out – In |

| Average CIP Frequency | 15-20 days | 25-35 day |

| Daily chemical maintenance (TMC)y | NaOCl / NaOH / HCl | NaOCl |

| Average recovery | 88% |

Result

After replacing the former Inge UF system with the “TORAYFIL” UF solution, Paper industries achieved improvements like: